Big Data is transforming oil and gas industry by enabling unprecedented levels of efficiency, safety, and profitability. Big Data in oil and gas is driving innovation as the industry faces mounting challenges: rising operational costs, volatile markets, and increasing environmental scrutiny.

Businesses may overcome the obstacles unique to their industry by utilising sensors, analytics, and other emerging technologies.

Oil and gas companies can finally automate costly, dangerous, or error-prone activities thanks to the quick development of big data and analytics technology and control systems.

Optimising operational efficiency is critical, given the significant increase in capital investment in energy equipment and services.

What is Big Data?

Big Data involves handling vast amounts of information from various sources, like sensors and software systems. This data helps oil and gas companies improve decision-making and operations.

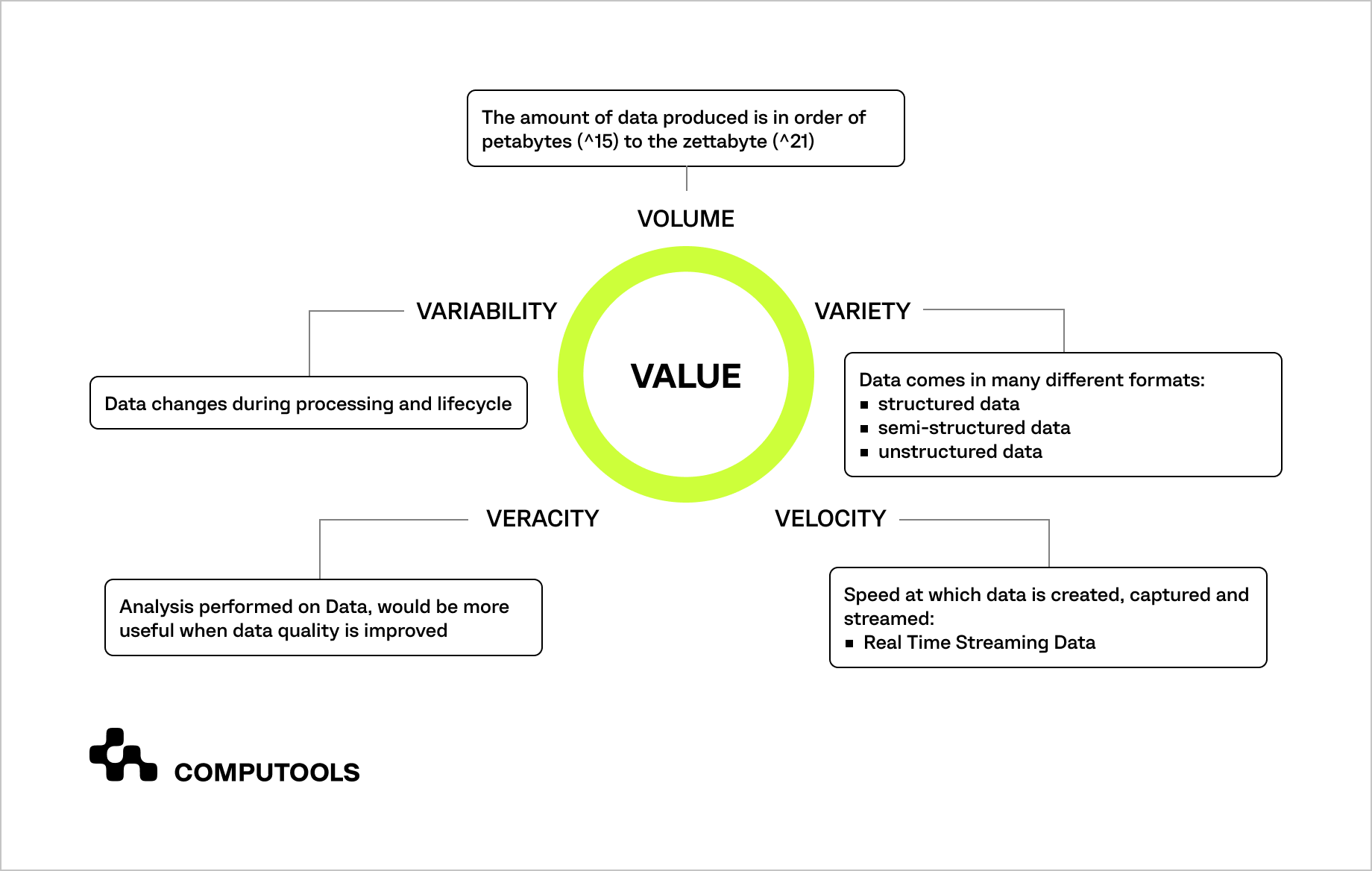

It encompasses several key characteristics:

• Volume: The sheer quantity of data from sensors or recording tools poses storage and processing challenges. Many companies struggle to analyse their vast archives, and Big Data tools address this by enabling efficient data processing and analysis.

• Variety and Velocity: Big Data includes diverse data types and requires rapid transmission and processing to extract actionable insights.

• Veracity: Data quality is critical for reliable analysis. Distinguishing clean data from dirty data ensures accuracy, particularly in the oil and gas industry, where subsurface data often includes uncertainties. Properly filtered data enables effective decision-making.

• Value: Big Data reveals trends and forecasts potential issues, such as equipment failures. This foresight provides a competitive advantage, enhancing operational efficiency and maximising returns on investment.

• Variability: Data evolves throughout its lifecycle, requiring adaptable processing tools to maintain relevance and accuracy.

An Overview of the Oil and Gas Big Data Market

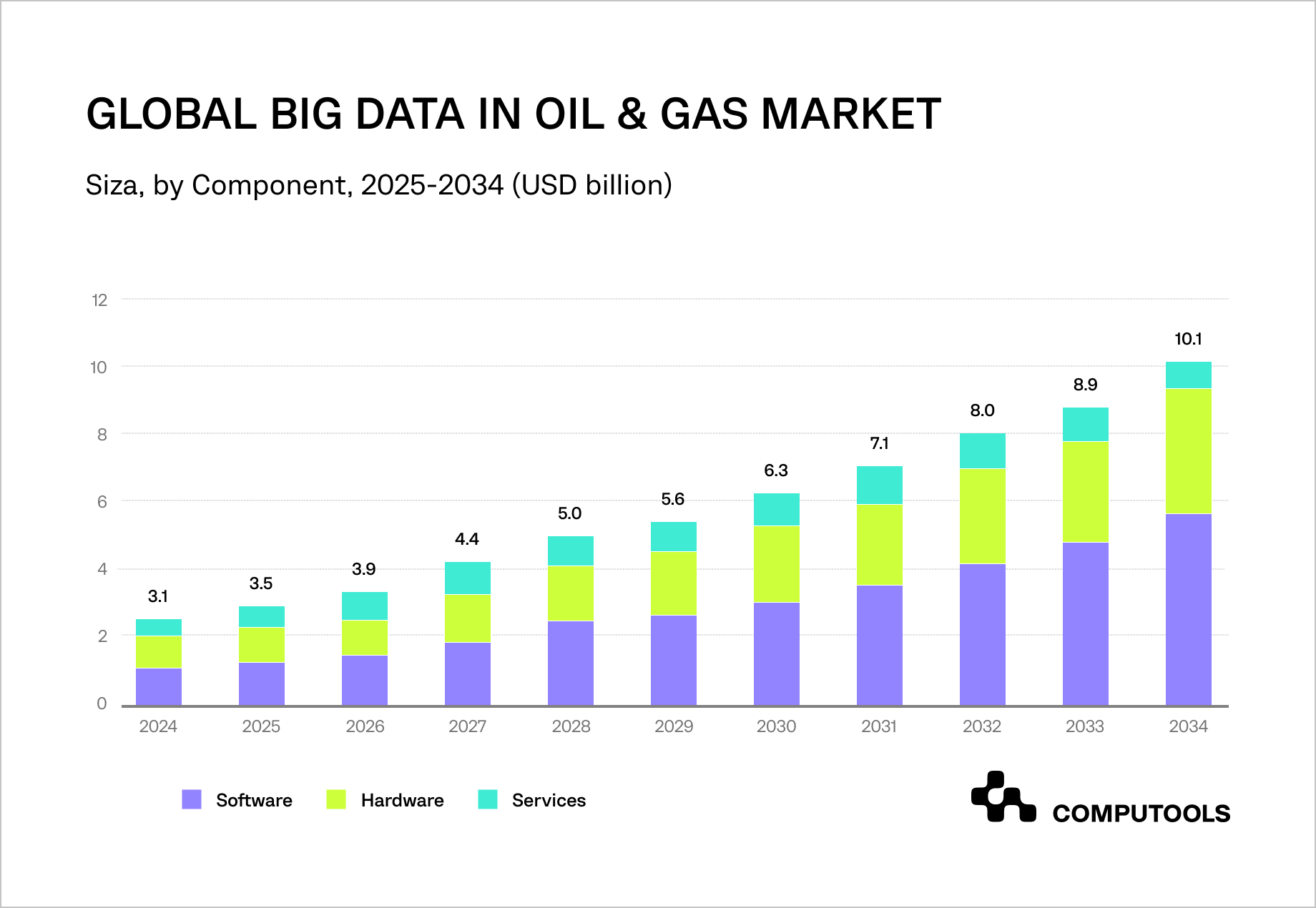

Our analysts’ research, which gathered information from multiple sources, predicts that the global market for big data in oil and gas will grow at a compound annual growth rate (CAGR) of 12.5% from 2025 to 2034, from USD 3.1 billion in 2024 to USD 10.1 billion by 2034.

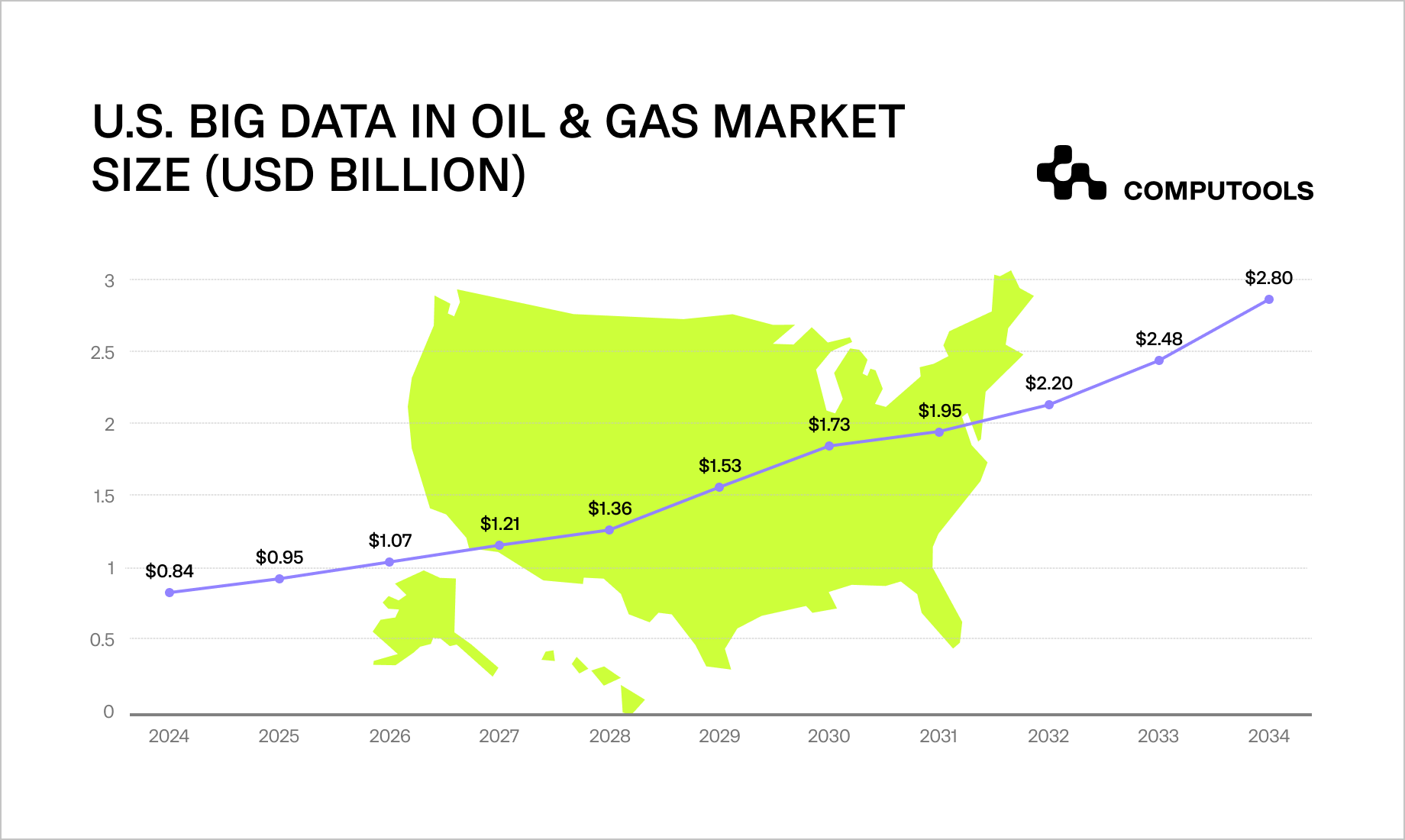

With more than 35.8% of the market share and USD 1.1 billion in sales, North America was the market leader in 2024. In the same year, the U.S. market alone brought in USD 0.84 billion, and it is projected to expand at a consistent CAGR of 12.8%.

The U.S. Big Data in Oil & Gas market reached USD 0.84 billion in 2024, demonstrating both quick expansion and innovation.

This leadership is a result of the United States’ sophisticated technology infrastructure, which makes it possible to integrate Big Data seamlessly to improve operations and decision-making.

Furthermore, a strong ecosystem of startups and tech companies emerges solutions through advanced data analytics in the oil and gas industry.

Importance and Benefits of Big Data Solutions in the Oil and Gas Industry

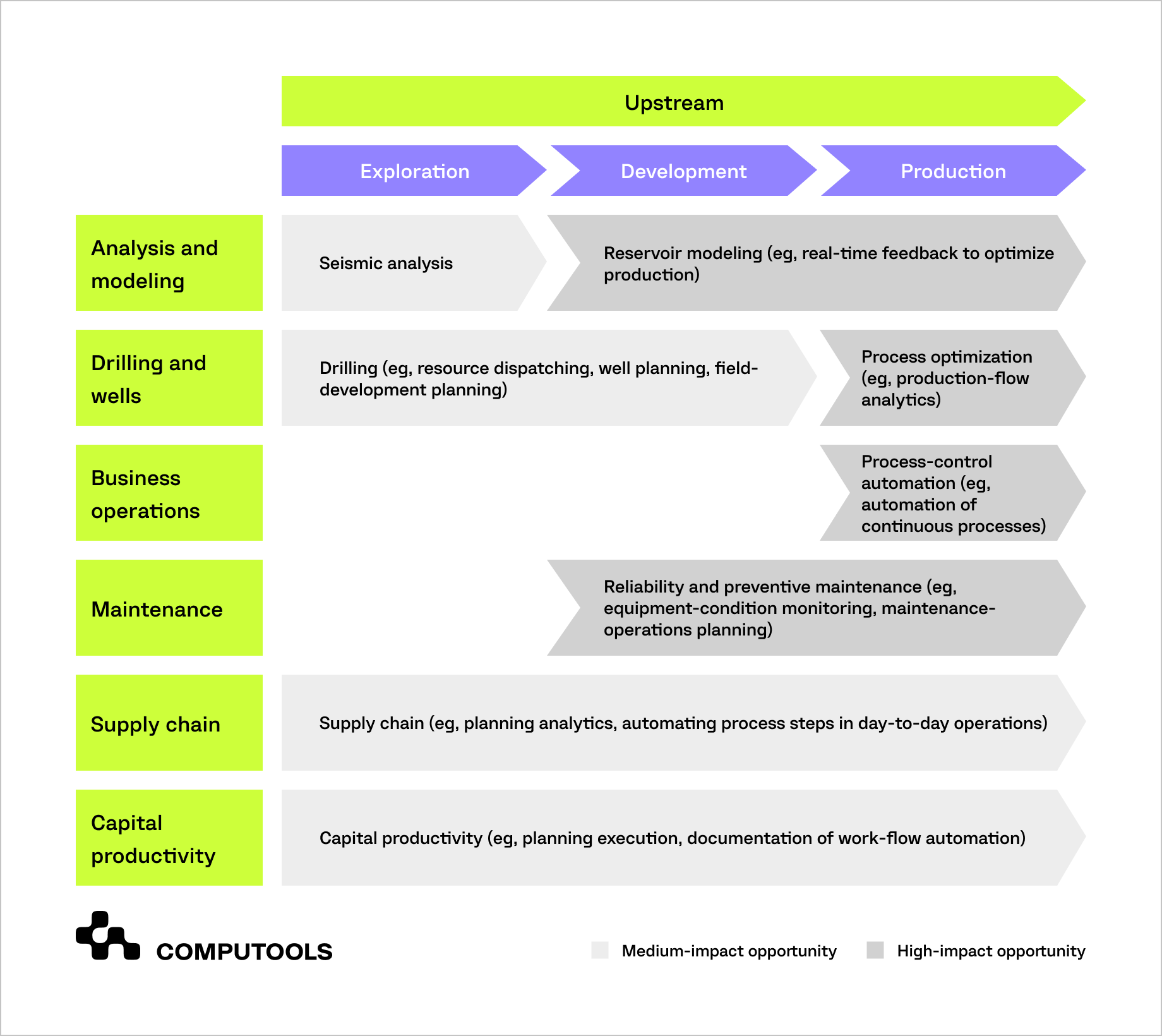

Production activities provide the most tremendous potential, such as lowering unforeseen interruptions. It is impossible to overestimate the importance of Big Data in the oil and gas business, given the substantial investments made in exploration and production; it is an essential instrument for accomplishing these objectives.

Big Data solutions transform manufacturing by increasing safety, cutting costs, and optimising efficiency. Big Data analytics for oil and gas is making it possible to optimise output without endangering human health, safety, or the environment. This increases production while also improving throughput and time.

On offshore platforms, high production volumes mean that even minor efficiency improvements can have a significant impact on financial results, as additional production directly increases revenue.

Carefully chosen automation steps can reduce costs and improve equipment reliability in low-volume environments in mature fields such as oil sands. These Big Data benefits not only increase revenue but also extend the economic life of the fields.

Here’s how Big Data in oil and gas plays an important role in automating processes in the industry:

• Data collection: Sensors and Internet of Things devices on production platforms constantly collect vast amounts of data on equipment status, production levels and environmental conditions.

• Data analysis: Data is analysed using machine learning and artificial intelligence technologies. The study identifies patterns and anomalies that can indicate possible problems or opportunities to optimise processes.

• Predictive analytics: Predictive analytics uses big data to assist in planning preventative maintenance ahead of time and anticipate equipment failures. This lessens the possibility of unscheduled downtime.

• Production Optimisation: Data analytics helps optimise the entire oil and gas production and refining process, improving efficiency and productivity. This includes enhancing equipment and well integrity, increasing production, and improving oil throughput.

For example, data analytics in the petroleum industry can drive these optimisations.

• Real-time decision-making: With Big Data, more informed decisions can be made in real-time, which is especially important in fast-changing production processes.

Random data is generally transformed into valuable, structured, and analytically relevant insights that help make production more efficient, safer, and cost-effective.

Moreover, the use of Big Data in the oil and gas industry allows for modelling different scenarios and determining the best management strategies, reducing risks and enhancing operational success.

Use Cases

1. Seismic Data Management

Companies like Shell use fibre optic cables in partnership with Hewlett-Packard for seismic sensors, transferring data securely to private servers maintained by Amazon Web Services.

Big Data analytics for oil and gas industry aggregates, cleans, and processes seismic data collected from sensors, enabling precise site selection and reducing risks, time, and costs.

2. Drilling Efficiency

Modern drilling platforms generate up to 15 petabytes of data throughout their lifespans, thanks to over 80,000 sensors per platform. This massive data enables predictive maintenance.

3. Reservoir Engineering

Big Data solutions empower companies to analyse critical downhole data collected via specialised sensors, such as temperature, pressure, and acoustic readings.

Advanced reservoir management applications provide actionable insights into reservoir conditions for control over operations.

4. Safe Logistics

Transporting petroleum safely is a persistent challenge in the industry. Big Data technologies, including sensors and predictive maintenance systems, detect faults like pipeline cracks or seismic ground movements, preventing potential failures.

These solutions ensure safer and more efficient logistics of petroleum products.

An Asian oil company’s deployment of advanced Big Data analytics showcases the transformative potential of digital tools. By implementing AI-driven YET optimisation at its refinery, the company improved margins by $0.10–$0.20 per barrel while cutting emissions and boosting the production of high-value products.

Over 18 months, the initiative generated $200–$300 million in additional value.

What Companies Lose by Not Adopting Big Data

Despite its clear advantages, only 36% of oil and gas companies have invested in Big Data analytics, with a mere 13% leveraging it for enhanced business intelligence.

Companies failing to adopt comprehensive Big Data solutions miss opportunities to minimise risks, optimise operations, and improve profitability.

Instead, they rely on outdated methods, losing a competitive edge in an increasingly data-driven industry.

Challenges of Big Data in Oil and Gas

Most oil and gas companies, irrespective of their locational base, also face other operational challenges of Big Data that make it difficult to achieve sustained production efficiency gains.

Utilising additional degrees of automation can ultimately help cope with the following challenges inherent in the given industry.

Here are the most common industry challenges that Big Data can help resolve:

1. More complex operations

Growing demands for volume and complexity in more hostile and remote environments, such as the Arctic, offshore, and deep-water applications, imply dependable remote and/or automated or semiautomated operating and logistic efficiency.

We also understand that mature and declining assets require production at very efficient maintenance costs.

2. Health, safety and environment-related incidents

This is an unqualified necessity. The past decade has revealed that, in the light of regulatory pressures, such occurrences pose a risk not merely to operating profits but, indeed, to the survival of many operators.

Real-time systems are now expected to include automated production control, equipment condition monitoring, and shut-down prediction systems to manage or avoid disasters in remote distributed locations.

3. Talent and experience differential

The industry is experiencing the largest generational change ever, called “The Big Crew Change.” The petrotechnical workforce’s biggest problem is rapidly approaching retirement, and thousands of pyrotechnical professionals are going to retire.

Retention and recruitment may not solve the problem completely. This evolution has led to the tendency to transform many of the basic analyses and the support of decision-making processes into explicit procedures, with a view to formalising and, as far as possible, formalising them.

Predictions for the Technology Usage in the Industry

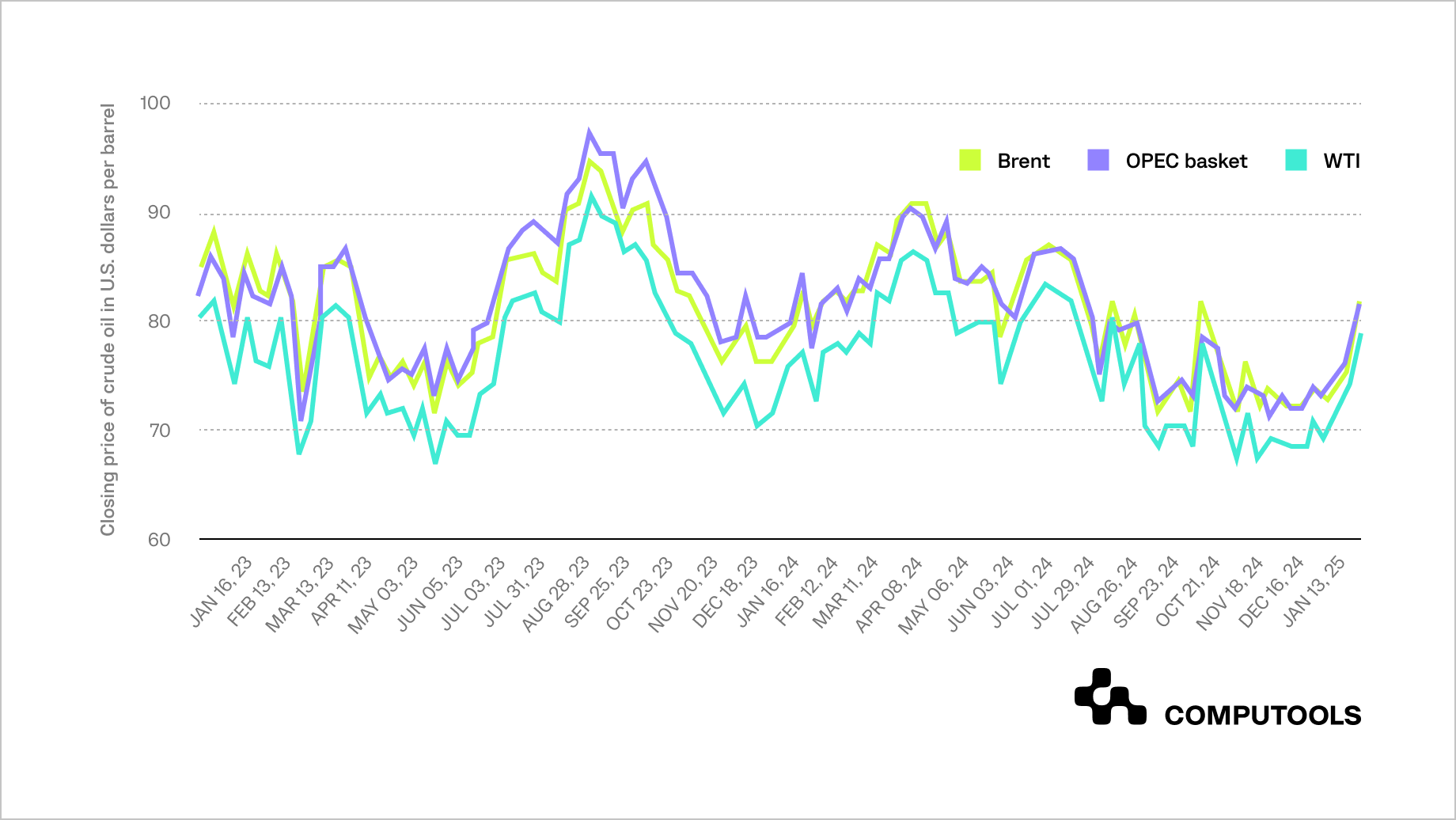

The oil industry is no stranger to volatility. For example, in January 2024, the spot price of a barrel of oil fell below $70, and a year later, it soared to about $90.

This volatility highlights the need for more intelligent, data-driven tactics and is caused by global events such as supply chain interruptions, demand changes, and geopolitical conflicts.

A revolutionary strategy is required due to the volatile nature of oil prices, growing operating expenses, a lack of skilled workers, and mounting pressure to lower carbon emissions.

By using real-time and historical data, advanced analytics models forecast pricing changes and enable businesses to make proactive strategy adjustments.

Big Data enables the precise identification of potential reserves through seismic data analysis and predictive modelling. Analytics tools assess geological conditions to recommend optimal drilling strategies.

Predictive maintenance powered by IoT sensors and machine learning reduces downtime and enhances equipment reliability.

Techniques like Yield, Energy, and Throughput (YET) optimisation boost efficiency while cutting carbon footprints.

These recent technological developments direct the future of Big Data to:

1. Wireless IIoT devices

Digital sensors in industrial settings collect major data streams by continuously observing key processes such as flow rates and temperature. Access to data and analytics tools lets you improve business processes while optimising your assets.

Oil and gas operations used 7.8 million wireless communication devices in 2023, supporting cellular, satellite, and LPWA connectivity solutions. Experts forecast this market will grow by 19.3% yearly before hitting 18.8 million units in 2028.

Energy software development plays a pivotal role in enabling these wireless systems to integrate seamlessly into complex industrial infrastructures.

2. AI and ML analysis

AI and ML programs help oil and gas businesses decode their intricate data systems. The system’s analysis detects upcoming equipment issues and optimises drilling techniques to reduce operating delays and increase output while saving money.

By 2026 forecasts predict that generative AI will increase output by 30% for oil and gas businesses. This innovation will perform everyday operations and boost managerial judgment effectiveness.

In 2025, companies practising AI best practices in their operations will create threefold returns that exceed the investment outcomes of ninety per cent of non-AI adopters.

3. Quantum computing

By 2030 quantum computers will unite existing advanced computation systems with developing technologies. Quantum technology plans to expand data processing abilities across the next decade and overcome big optimisation tasks that current computers lack the power to solve.

Global energy leaders ExxonMobil Shell and BP have begun funding quantum technology projects to advance both their innovative capabilities and sustainable operations.

4. Digital twins

The next step allows digital twins to automate drilling operations by integrating robotic and autonomous technology.

They enhance gas network smart grids to improve supply chain performance and reliability. Chevron produces matching digital versions of its sites to examine and forecast actual facility performance.

Through this method, users track and forecast machine functionality at any time, either locally or at distant locations. Data engineering services create and manage these sophisticated digital twin models.

5. Cloud computing

Seismic data produced at higher rates through exploration and production exceeds the processing capabilities of standard data management systems. Cloud platforms let users access and analyse massive datasets at reduced costs using their elastic computing resources.

The oil and gas industry spends billions on energy equipment and services and expects steady growth. SaaS solutions lead to an increase in cloud computing use, supported by cutting-edge data analytics services that drive meaningful insights from complex data.

6. Data governance

The oil and gas industry now demands strict data governance and security standards as we approach 2024. Modern security systems and advanced governance standards must keep up with data complexity, AI progress, and the environment.

According to Immuta’s State of Data Security Report data, professionals dedicate about 35% of their efforts to update data governance and security policies. Six out of ten industry professionals worry about AI prompting systems revealing confidential data.

Despite the potential of Big Data, only 30% of oil and gas companies have scaled their digital initiatives successfully. Challenges include demonstrating clear value from technologies, overcoming employee resistance, and integrating new systems into legacy infrastructures.

Companies must adopt a holistic approach to digital transformation by:

• Focusing on Value Creation: Prioritise projects with tangible business outcomes.

• Tracking Impact: Use robust KPIs and visualisation tools to monitor progress and ensure financial thresholds are met.

• Building the Right Culture: Offer training, incentives, and support to employees adapting to new technologies.

• Investing in Infrastructure: Integrate modern IT systems with legacy setups for seamless operations.

As the Fourth Industrial Revolution continues, technologies like AI, IoT, and blockchain are maturing rapidly.

These advancements, coupled with Big Data, will empower oil and gas companies to adapt to market shifts, maximise resource utilisation, and align with global sustainability goals.

Leaders who embrace these innovations are well-positioned to thrive in an era of heightened competition and complexity.

How to Implement Big Data in Oil and Gas Processes

Companies that have successfully implemented automation and digitalisation programmes look at their initiatives from a full lifecycle cost and cost-effectiveness perspective.

At Computools, we provide tailored solutions to help businesses achieve this through:

1. Building a Digitalisation Team

We form dedicated teams to integrate automation into corporate digital transformation programmes, ensuring that every process aligns with the company’s strategic goals.

This approach is backed by our portfolio of successfully implemented projects, like how we helped a sustainable energy supplier reduce downtime and improve turbine performance by using predictive maintenance driven by artificial intelligence-powered data analysis.

2. Programme Integration

Automation isn’t just about deploying technology—it encompasses all aspects of a company’s workflows and their interaction with human factors.

Computools focuses on adapting processes and employee behaviour for maximum efficiency, leveraging our software development company’s expertise to provide comprehensive and innovative solutions.

3. Piloting and Testing

Industry experience and prudent risk management demand thorough testing through small-scale pilot projects.

We help businesses minimise risks and validate concepts effectively, drawing on feedback from our clients to continually refine our methods and ensure top-quality outcomes.

4. Rapid Scaling

Once a pilot project has been validated, rapid scaling becomes essential to unlock its full economic potential. Computools has the tools and capabilities for technology-driven transformation and the ability to manage risks and adapt approaches.

Our development expertise in Big Data solutions and energy software development positions us as a reliable partner for scaling projects efficiently and strategically.

Why Computools?

The key to successful Big Data implementation in the oil and gas industry lies in choosing an expert partner with a proven track record in the sector.

At Computools, our key idea is to approach digitalisation strategically: start small but plan for future growth to maximise the benefits of the technologies being deployed.

See how we’ve driven success in similar projects, or read feedbacks from our clients to understand the value we bring to the table.

Discover how Computools can help your company transform processes and achieve success by visiting our case studies.

Partner with Computools for customised Big Data solutions. Contact us today at info@computools.com for free expert consulting.

Computools

Software Solutions

Computools is an IT consulting and software development company that delivers innovative solutions to help businesses unlock tomorrow.

“Computools was selected through an RFP process. They were shortlisted and selected from between 5 other suppliers. Computools has worked thoroughly and timely to solve all security issues and launch as agreed. Their expertise is impressive.”